Galzigbahn

- St. Anton

Galzigbahn

- St. Anton Galzigbahn

- St. Anton

Galzigbahn

- St. Anton

History retold and the beginning of a new age

Film over the Galzigbahn >>>>

Film over the Galzigbahn >>>>

Already in 1937 the people of St. Anton am Arlberg were very

concerned about the attractiveness and the international competitiveness of the

town. As one of the first Austrian towns with a cable cars St. Antons cable car

on its Galzig mountain was

mainly used for winter business, unusually, as up until this time in Austria it

was primarily a summer business. Davos and St. Moritz were one of the few Swiss

towns that used thier cable cars in the winter.

The permanent secretary for foreign affairs, Dr. Guido Schmidt and the president of the Tyrolean industrialist union, federal economic council KR, Dip. Ezio Foradori had substantially contributed to the building of the Galzigbahn. Following the opening of the Galzigbahn on December 19th, 1937 both men were appointed honorary citizens of the municipality of St. Anton.

The

carrying capacity of the Galzigbahn was 210 persons per hour at this time, a

cubicle held 30 persons and with almost 60.000 transported persons recorded a

great success in the first year of operation.

The

carrying capacity of the Galzigbahn was 210 persons per hour at this time, a

cubicle held 30 persons and with almost 60.000 transported persons recorded a

great success in the first year of operation.

For over 70 years, guests from all the world have valued the direct connection from the valley to the Galzig, as a starting point for skiing or simple enjoying the sun, a great view and a good meal, all at 2070m.

Over 40 years ago in 1964 the Galzigbahn was modified for the last time. The carrying capacity of 700 persons per hour, with time, has become too little. To reduce the exploitation of the Galzigbahn and therefore waiting times in the valley, the Gampenbahn was modified from a double chair lift into a 4man chair lift in 1990. But on peak days this extra capacity is no longer sufficient today to avoid waiting times. An additional factor is that many guests prefer to reach the Galzig directly and without a detour via the Gampen. Also uncomfortably -- quite particularly for families with children and beginner skiers, is the steep staircase, that leads to the entrance of the Galzigbahn. To

keep pace with the high standard of the other cableways and lifts in St. Anton

am Arlberg, the new building of the Galzigbahn is the consistent next step. But

a reorganisation alone, seems too little for the historical cable car, one

requires, like in 1937, new standards for the future to be set with the

rebuiding of the Galzigbahn.

To

keep pace with the high standard of the other cableways and lifts in St. Anton

am Arlberg, the new building of the Galzigbahn is the consistent next step. But

a reorganisation alone, seems too little for the historical cable car, one

requires, like in 1937, new standards for the future to be set with the

rebuiding of the Galzigbahn.

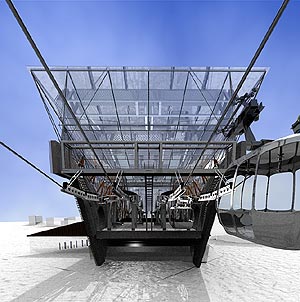

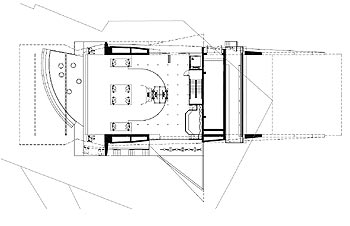

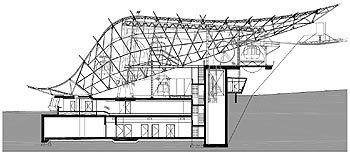

The ultra-modern Funitel system combined with a cableway technical world first shall make this possible. With the help of a "Ferris wheel" it manages to make an entryway at ground level possible for the guest by the individual gondolas from above coming over the wheel to floor height and after the getting in in up and over the wheel again. The Funitel contains 28 cubicles each for 24 persons, 18 sitting and 6 standing, with a speed of 6 m/sec, this triples the previous carrying capacity of the Galzigbahn. This also means that besides the comfort on entry, waiting times are a thing of the past.

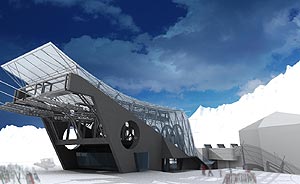

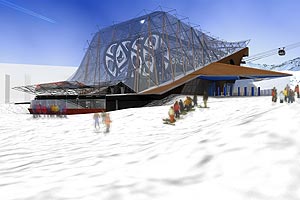

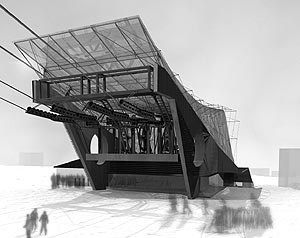

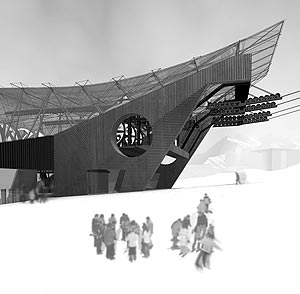

But

breathtaking technology is only one of the highlights of the new cableway which

will be ready for the winter 2006/20007 season. The architecture of the valley

station of the new Galzigbahn is as well fascinating. Timeless elegance in the

building underlining ultra-modern cableway technology - were the standards set.

For the Tyrolean architect Georg Driendl this was right up his street, his claim

to create a transparent, dynamic main body which shows on the outside what one

experiences on the inside. The architecture of Driendl provides future-oriented

promotion technology and the spectacular sequence of movements visibly into the

centre. The offices currently located in the building will be moved so that the

focus will be excusively on the cableway, a fusion between building and

technology, nature and sports, quiet dynamics and speed - Architect Georg

Driendl starts a new era.

But

breathtaking technology is only one of the highlights of the new cableway which

will be ready for the winter 2006/20007 season. The architecture of the valley

station of the new Galzigbahn is as well fascinating. Timeless elegance in the

building underlining ultra-modern cableway technology - were the standards set.

For the Tyrolean architect Georg Driendl this was right up his street, his claim

to create a transparent, dynamic main body which shows on the outside what one

experiences on the inside. The architecture of Driendl provides future-oriented

promotion technology and the spectacular sequence of movements visibly into the

centre. The offices currently located in the building will be moved so that the

focus will be excusively on the cableway, a fusion between building and

technology, nature and sports, quiet dynamics and speed - Architect Georg

Driendl starts a new era.

To keep the attractiveness of the cableway also at night work, the building is lit, moreover, two gondolas will be at the Ferris wheel overnight to illustrate fascinating technology.

Technical basic data:

| Height of valley station | 1319m |

| Height of top station | 2085m |

| Position of the motor | in the top station |

| Situation of the weight pully | in the valley station |

| Rope diameter | 52mm |

| Total length rope | approx. 10450 m (approx. 110 tons of total weight) |

| Carrying performance | 2200 P/h |

| Max. speed | 6 m/s |

| 28 cabins | 24 persons each |

| Journey time | 9.14 min |

| Motor performance | 4 engines per 500 kW/2 transmissions |

Arlberger

Bergbahnen AG: Short profile

Arlberger

Bergbahnen AG: Short profile

In the course of the building of the Galzigbahn, the first cableway of the Arlberg, the Bergbahn AG, today Arlberger Bergbahnen AG was founded in the year 1937.

Today, 86 cableways and lifts as well as 276 km of ski runs and 174 km back country tracks offer a variety of possibilities. St. Anton am Arlberg has slopes for all tastes, varying from those looking for the comfortable family runs for beginners to those who prefer the demanding steep slopes and high alpine tours. The company invests every year into new, ultra-modern lift systems as well as in regular improvements in the slopes and customer services sector to offer its customer the highest possible comfort.

In

the financial year 2004/2005 Arlberger Bergbahnen AG recorded a turnover growth,

like also in the previous years, and achieved € 30.4m as well as an

unappropriated retained earning of €2.4m. The company employs, in the winter

season, 255 employees in the area of the mountain lifts and slopes and another

110 employees in the restaurant area. In the summer season there are 15

employees in the restaurants and in the lift operation 145.

In

the financial year 2004/2005 Arlberger Bergbahnen AG recorded a turnover growth,

like also in the previous years, and achieved € 30.4m as well as an

unappropriated retained earning of €2.4m. The company employs, in the winter

season, 255 employees in the area of the mountain lifts and slopes and another

110 employees in the restaurant area. In the summer season there are 15

employees in the restaurants and in the lift operation 145.

Further information:

Arlberger Bergbahnen AG

Tel: +43/5446/2352-0, fax: +43/5446/2352-102

office@abbag.com, www.abbag.com

Siemens

technology

Siemens

technology

The Siemens Industrial Solutions and Services (I&S) Group has received an order from Arlberger Bergbahnen AG to equip the new Galzigbahn ropeway in St. Anton, Austria, with drive and automation systems.

The drive equipment of the Galzigbahn ropeway will be accommodated in the top station. Siemens is supplying four direct-current machines for the equipment, each machine having an output of 500 kilowatts and being supplied via four 1600-ampere converters. The entire ropeway as well as the big wheels will be controlled with fail-safe programmable controllers of the Simatic S7 series. Siemens is also responsible for engineering, installation and commissioning.

|

|

|

|

|

|