The PistenBully 600 opens up a new dimension in piste grooming. Both technically as well as in terms of design.

Kässbohrer Geländefahrzeug AG

The PistenBully 600

Where the future of piste preparation lies!

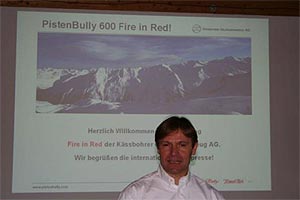

Laupheim, 23rd January 2006. Kässbohrer Geländefahrzeug AG is presenting the new PistenBully generation on its FIRE IN RED Tour throughout Europe. FIRE IN RED stands for state-of-the-art technology and red-hot design in the world market of piste vehicles.

An initial glance into the cockpit of the new PistenBully 600 gives away what it’s all about. Concentration on what's important: the driver. The PistenBully 600 has come up with a wealth of first-class technical equipment – ergonomics, drive comfort and ease of operation are always in focus. The driver's seat has been completely revamped. It has a greater adjustment range and the winch machines have an integrated harness belt attachment directly onto the swing-action seat frame. This is important for drivers who often sit in the PistenBully for several hours at a stretch. The semicircular steering wheel with built-in multifunctional display is a new development as a result of ergonomic requirements. The height and reach of the steering column is steplessly adjustable, ensuring that the new semicircular steering wheel is in the ideal position. Large-area glazing extending well down ensures optimum all-round vision. Above all, the side windows allow a very good view of the chains. The generous space provided enhances driving comfort at the workplace.

As there was no joystick available on the market to meet Kässbohrer requirements in terms of ergonomics and driver comfort, a new joystick was developed. Now the driver no longer has to hold the joystick tightly, but rests his hand on it from above. This has allowed more functions to be incorporated in the joystick at the same time as pleasant, fatigue-free handling. Switches are located to suit the natural movement radii of the fingers. To make it easier to find the most frequent work positions as far as winch pulling force and contact pressure of the tiller are concerned, the joystick has a potentiometer with a detent function.

Both drivers who have been using a PistenBully for years as well as people with less experience can use the intelligent assistance systems entirely according to their own individual requirements and preferences. Self-explanatory controls and a touch-screen make it extremely easy for the driver to operate the system. The entire vehicle is shown on the control panel. Thanks to the logical icons, the driver can find his way around immediately. He doesn't have to remember which switch is used for which function, but simply presses the icon for the appropriate vehicle part. For example, if he presses the tiller, it is lowered. All functions can also be controlled using the I-command, which is integrated into the armrest.

The design of the new PistenBully 600 exudes action and energy. The autonomous design adapts harmoniously to the historic development of the PistenBully. Distinctive lines like those of the door hinge area have been consistently pursued. Some design elements have nonetheless fundamentally changed. Designers have thereby developed a very modern language of shape which expressively embodies the brand values and character of a PistenBully.

The PistenBully 600 opens up a new dimension in piste grooming.

Both technically as well as in terms of design.

All front headlamps and the twin searchlights are integrated in the roof of the driver’s cab, ensuring outstanding long-range and working-area illumination. The two glare-free rear spotlights mounted in the rear wall of the roof provide an optimum view of the tiller and piste. The standard lighting package includes xenon working lights and SideFinder lights which illuminate the side and rear working area of the clearing blade. The xenon lighting package is available as an option and has all front and rear headlights in xenon design. In order to illuminate the side area better, there are now the new Treeline lamps which ensure better illumination of the side area. When the door is unlocked using the remote control, the entry illumination and service lighting in the engine compartment are activated automatically, thus providing good illumination of the supporting frame area even off-road.

Precision handling in any situation is guaranteed by the finely tuned running gear, the main frame of which consists of high-strength fine-grain steel that is extremely resistant to cold temperatures. Calculation of the frame using the finite element method has allowed a frame structure with less indentation. Optimally positioned connecting points for the scoop frame and rear attachment carrier guarantee ideal pushing and surface levelling results.

The new PistenBully 600 sets out with a 6-cylinder engine and 400 hp. The generously sized drive pumps with integrated pressure cut-off and servo control and the weight and performance-optimised planetary gearbox ensure optimum efficiency with adequate reserves of torque. The folding transportation platform, introduced with the PistenBully 300 Polar, has been adopted on the PistenBully 600. It is the ideal solution for safely transporting company staff on the platform.

The driver-friendly cockpit sets the standard when it comes to

design and ease of operation.

Intelligent control and positive diagnosis: the PSX controller is the host computer in the vehicle for central power and energy management. The diesel engine and drive/tiller pumps are directly controlled via CAN signals. The oil quantity distribution of the working hydraulics and the automatic tiller depth function are also controlled by the PSX controller. All sensors and actuators switch automatically into failsafe mode if necessary. Use of non-contact sensors ensures very high operational safety and reliability. The diagnostic functions of the individual components and operational data have once again been further developed, ensuring that the driver always knows exactly how things are with his PistenBully.

Countless quality tests and consistent quality management as early as the development phase have made the new PistenBully a vehicle in which all components are exactly intermeshed. In order to guarantee safety in the vehicle, a prototype has to withstand spectacular tests such as the so-called pendulum impact test, which tests the stability of the windscreen, the ROPS test and the cold chamber test. In parallel to the quality assurance measures in the development and production at Kässbohrer itself, quality also has to be assured in the case of supplier companies. Whether in the production of tools and models using 3D milling data with optimal repeatability or the precision testing of specimens to the production of serial parts, Kässbohrer quality testers are always keeping a watchful eye on it all.

In the cockpit and on the semicircular steering wheel and

joystick, all buttons and control lights are logical and are colour-coded

according to the vehicle functions.

There is a generous feeling of space and extra comfort in the new PistenBully 600. Equipment is designed to meet the most stringent demands. The extensive basic set of standard equipment is supplemented with options that give free rein to individuality.

With the generation change, the PistenBully 600 can develop its advantage over the competition. The new PistenBully is unique in terms of ergonomics, drive comfort and design, as well as in terms of technology such as the innovative assistance systems and precision running gear. The lead over the competition is not only expressed in running performance, but is also noticeable in the drive experience and quality of the interior. The new generation raises the yardstick yet another notch higher in terms of design, drive dynamics, safety, ergonomics and driver orientation.

The new SideFinder lights illuminate the edges of the clearing

blade from the rear as well as from the side.