Prinoth: Does a good piste appearance also mean lasting piste quality?

Dolomites, nine in the morning.

The first skiers are already on the lift. They want to be the first ones to

race down freshly prepared pistes. Nothing more can be seen of the lively night

time activities, which could only be imagined from the bottom of the valley from

the blinking and flashing lights the evening before. The snow groomers were on

the move for hours as they moved tons of snow uphill, from the edge of the

pistes to the middle, from those hollows where there is always snow to the

places where every skier stops by to enjoy the view or wait for his friends.

In the morning, there is nothing more to be seen; the entire width of the pistes

is covered with a uniformly thick layer of snow. Everything is smooth, flat, and

uniformly grooved, as though the entire width was prepared in one pass.

Skiers have perfect conditions every morning, but, behind high-quality piste

preparation, there is much more than just racing a groomer at top speed over the

icy and spent pistes created by thousands of skiers carving their way downhill

during the course of the day.

Precisely here is the difference: You see, piste appearances are not the same as

piste quality!

But, what’s the difference?

This can be defined relatively easily – it is found in one important

detail: Do the late risers, who only get their skis on around lunch time, still

have the same conditions as the ones who definitely wanted to be the first on

the slopes? Or, are the icy sections that appeared the day before visible once

again and prevent skiers from carving their way down the hill?

The first step, especially for the extremely popular runs, is to use the

front scraper blade.

That way, ice crusts can be broken up and snow pushed back into the piste. The

hard, icy subsurface is covered with this loosened snow and results in a well

aerated layer of snow on a solid subsurface. Then, the tillers are used to grind

up larger lumps of snow and then once again loosen and aerate the top layer of

snow. In order to give the piste its characteristic uniform and regular pattern,

the finisher is drawn over the snow cover at the end. This results in perfect

pistes where the consistency provides maximum skiing enjoyment right into the

afternoon.

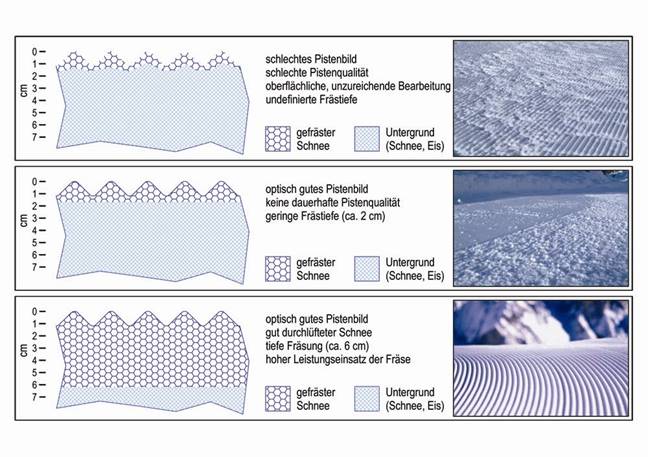

For less steep and less used runs, simply using the trailing tiller may be enough. Here, you must pay attention to the driving speed, the rotational speed of the tiller, and the tiller depth. The deeper the snow cover is processed, the more durable the resulting piste. For this purpose, powerful machines and ancillary equipment is needed that are specifically designed and developed for this. Here, it is mainly the positioning and the number of tiller teeth on the tiller shaft that plays an important role. By optimally choosing these parameters, you get a well aerated, lump-free volume of snow that freezes into a compact layer over night.

Many people are deceived by what looks to be a perfect piste appearance. Such a deception can be created with relatively little effort. However, the snow cover is only prepared to a depth of 2 cm, which can only stand up to a few skiers. After one or two hours, the upper layer of snow is gone and the surface is smooth as glass once again. The imprints of the caterpillar tracks shouldn’t be visible in the piste pattern, because this indicates fast and sloppy piste preparation.

It is very easy to recognise those ski regions where the “PISTE product” and consequently the enjoyment of the paying guests are not of primary importance. This could certainly have a positive effect on the annual balance sheet because fuel and personnel costs can be kept low, however, this type of speculation can easily lead to the enthusiastic ski guest looking for a different vacation destination in the following year. Basically, all ski regions offer one thing: ski pistes for a good time, and for exactly this reason, operators make piste quality top priority.

Martin Runggaldier, Manager of Research & Development at PRINOTH, added

the following: “Piste preparation is time-consuming, requires powerful

machines, optimally matched ancillary equipment, hard-working drivers, and

operations manager who know what is important.

We at PRINOTH supply the optimum work equipment for this. The investment pays

off in the long-term in any case – satisfied customers and high utilisation of

the lift systems speak for themselves.